Our Products

Our products and services are based on over 30 years experience of engineering excellence and sustained innovation. We own more than 25 varied rotary swaging and tube end forming machines, being capable of shaping tubes in diameters from 203mm to less than a millimeter.

Our skilled craftsmen can build tooling to accommodate intricate tube designs, to precisely shape a range of metals including brass, stainless steel, duplex, super duplex and inconel.

To complement our tube swaging and end forming experience we have qualified TIG and MIG welding engineers, assembly skills and can accommodate a range of solutions from one off prototypes to a run length of thousands.

Our ISO 9001 approved processes include processes and procedures to assure quality and manage full material traceability and PMI testing.

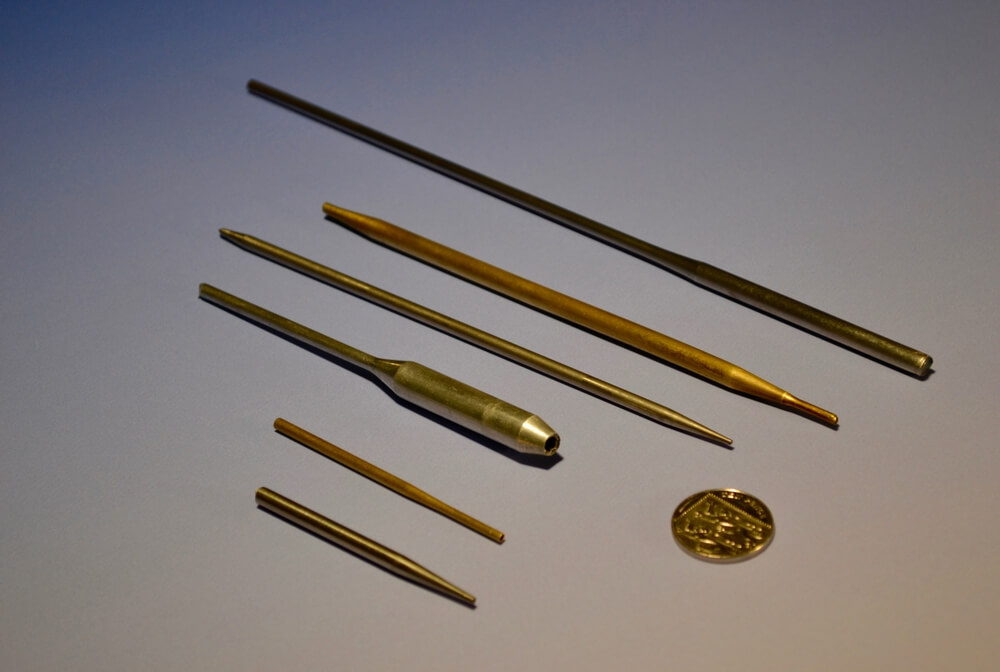

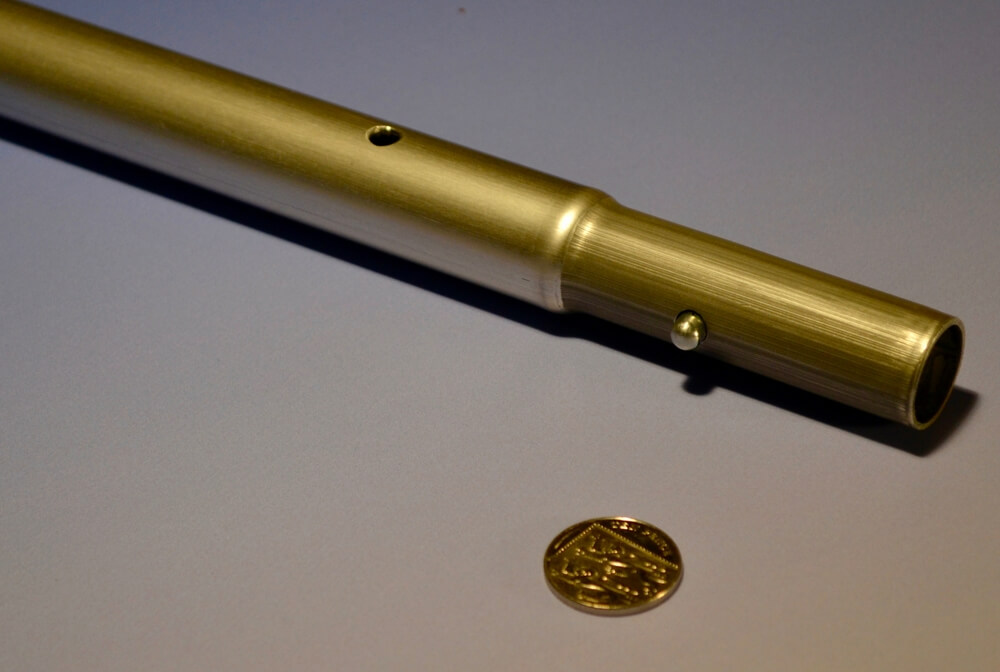

Swaging and tube forming

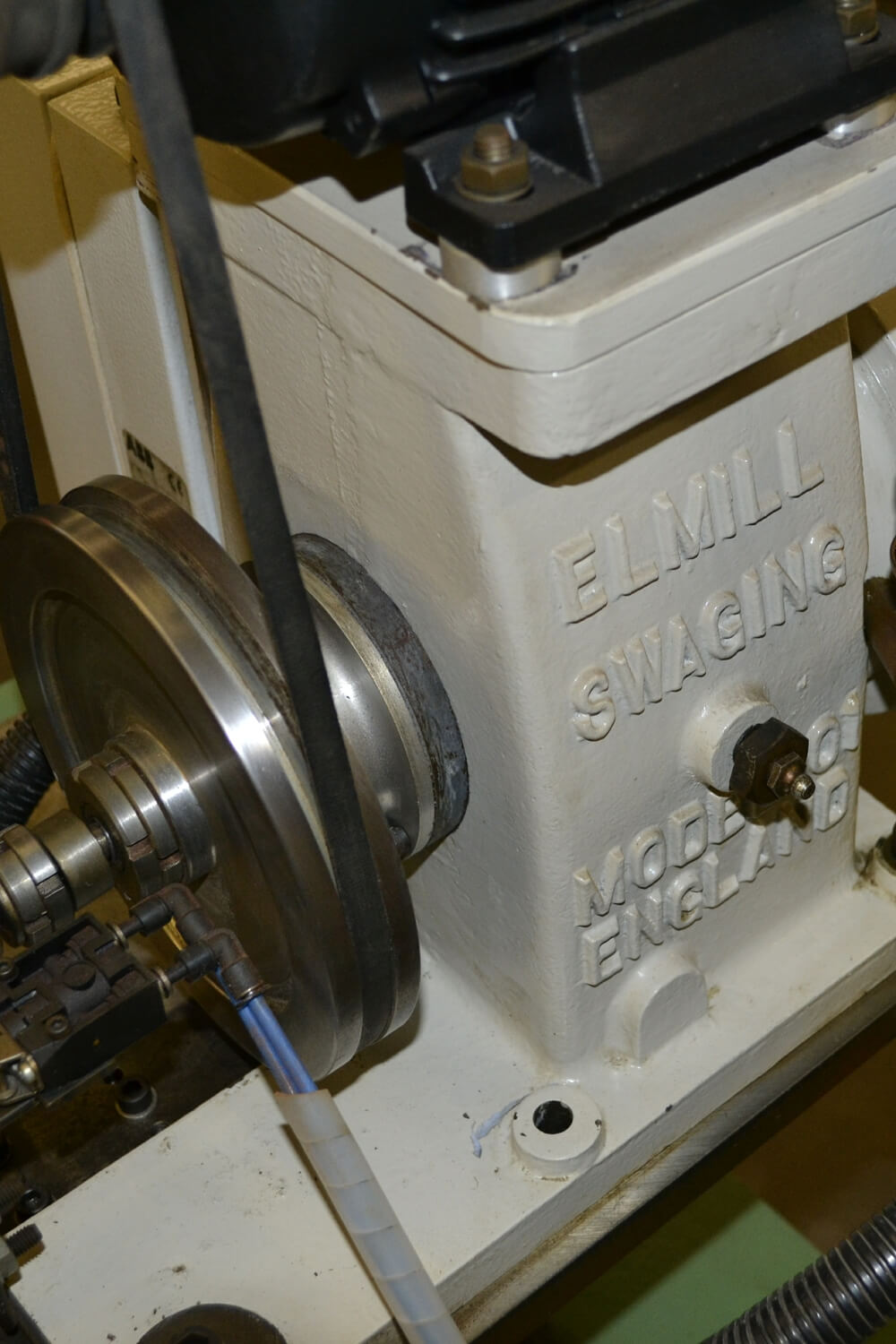

Swaging is the cornerstone of Elmill. Our engineers have over 30 years combined experience of rotary swaging tubes, pipes and bar, refurbishing rotary swaging machinery and swaging tool making.

Taper swaging

Tapering to produce a critical O/D or I/D.

Tube end-forming

Hydraulic pressure applied to shape the tube ends.

Tube reduction

Various methods including push pointing to reduce tube diameters.

Tube expanding/flaring

Tube expansion – hydraulic pressure to expand the end of the tube. Tube flaring to widen the end of the tube.

Solid bar reduction

Swaging or tapering solid bar to reduce diameter or shape the end.

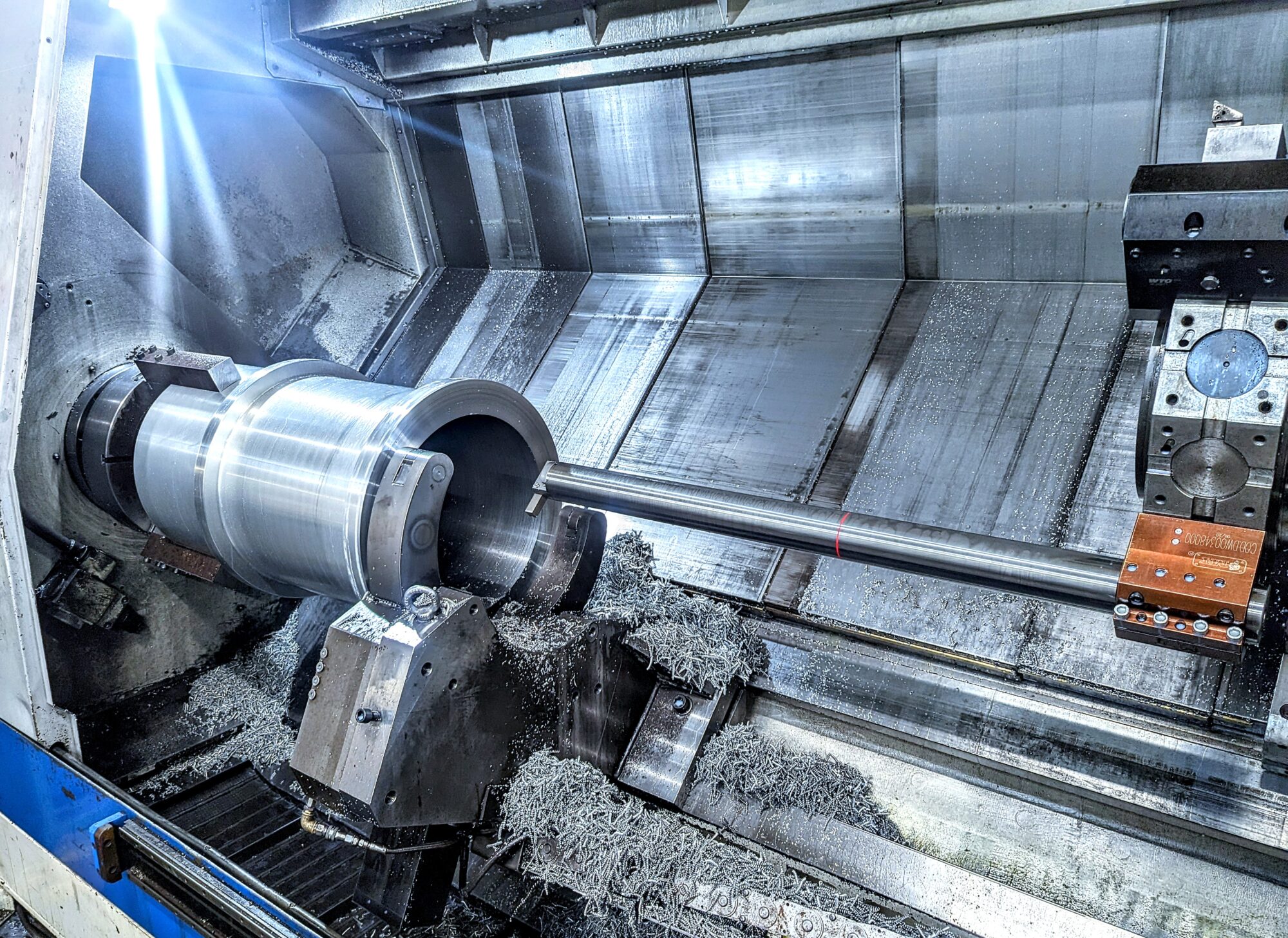

CNC Precision Engineering

We have CNC machining capacity on a range of machines to manage:

- Mills – X machines

- Capacity of XXXX

- Lathes – X machines

- Capacity of XXXX

Welded Assemblies

In house TIG and MIG qualified welding teams can combine swaged and precision engineered components to manufacture welded assemblies ranging from complex hydrocyclones in the oil and gas sector to simple bespoke parts.

We have experience of working alongside designers at the concept stage to help develop robust repeatable solution designs which are fit for manufacture. Our innovative approach has helped turn ideas into viable solutions.

- Chairs

- cyclones

- coach frames

- chiller trollies

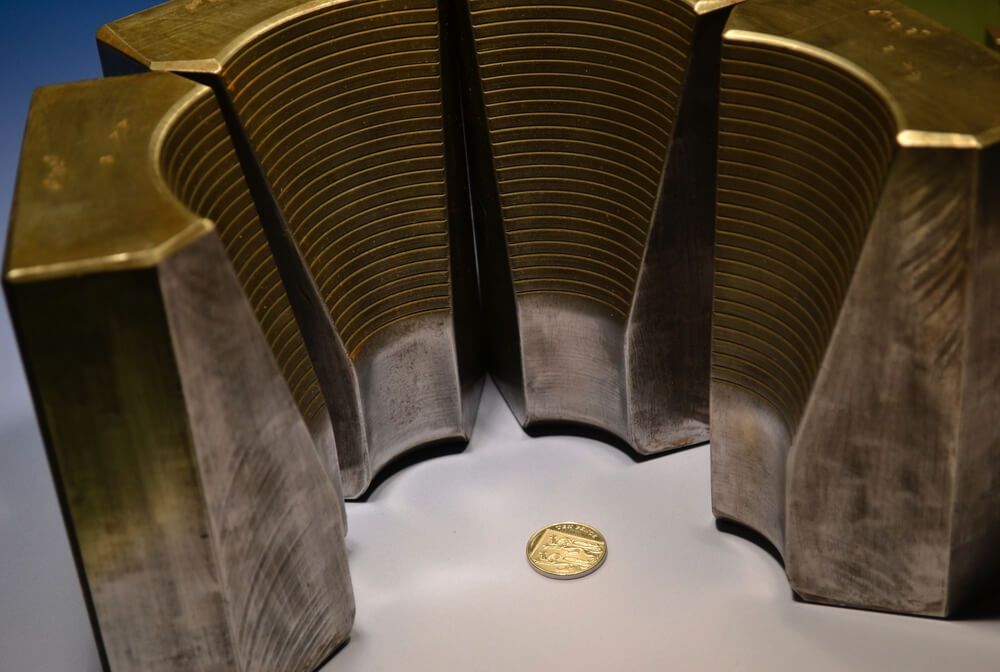

Toolmaking for Swaging Machines

We have in house capability to design and build tools and dies for swaging machines and end forming machines. We are able to make dies for our range of over 25 machines to accommodate bespoke tapering and shaping.

- Swaging machine dies

- End formers

Machine Inspection

Responding to the increasing demands for documentation and evidence based quality records in our markets, we have invested in a number of areas to support our material identification and documentation processes. This includes material etching capability and a handheld Niton XRF analyzer for Positive Material Identification (PMI) testing which can be performed on location.

PMI Testing

We have several trained engineers who are able to carry out PMI testing at the completion of the production process – or as a separate testing exercise on location. Detailed PMI audit reports are prepared from downloaded information.

Machine Inspection

Our engineers carry out rotary swaging machines inspections, service programmes and ad-hoc repairs. We also have a range of maintenance plans. We stock a wide range of Stevens and Bullivant rotary swaging machine parts and are able to manufacture parts to demand.

Etching/Marking

Part-marking is a service included as part of the manufacturing process and is an increasing requirement for many sectors.

Refurbished Swaging Equipment sales

Besides offering sub-contract swaging, we can offer longer term solutions for machinery and tooling equipment.

- Refurbished swaging machines

- Maintenance programs

- Bespoke tube end forming machines

We have proudly held ISO9001 for over 25 years.